How an AMECO Reclaimer is Reducing GHG and Utility Bills For Kentucky Largest Power Utility

3-in-1 by AMECO: Better CCR recycling, less GHG and more revenues for Kentucky’s largest power utility

The Challenge

LG&E KU, Kentucky’s largest power utility, struggled to handle the volume of CCR materials such as fly ash, bottom ash, and gypsum left over after its Trimble County plant burned coal to make electricity.

The root cause was relying on dozers that were often used for other tasks and had frequent downtimes and staffing issues. Moreover, handling these materials outdoors exposed workers and the environment to harmful dust.

Last but least, there was growing pressure on LGE&KU from its stakeholders to deliver short-term solutions to reduce the overall GHG impact generated by the plant.

The AMECO Solution

By their very nature, AMECO’s reclaimer systems (PSx) are designed and built to handle massive amounts of material in a straight line. As a result, the automated system reduces the need for manual labor, reducing the risk of accidents and injuries to workers. The system’s advanced control also ensures consistent and accurate handling of the CCRs, reducing the risk of errors and inconsistencies. Moreover, the dust collection system significantly reduces dust emissions, ensuring compliance with environmental regulations and reducing the risk of contamination.

Additionally, AMECO Group offered LG&E our unique value proposition that the competition could not match:

- Made of high-quality steel for optimal robustness

- Built by a well-trained workforce

- Improved the volume of material output by avoiding random variability of using dozers

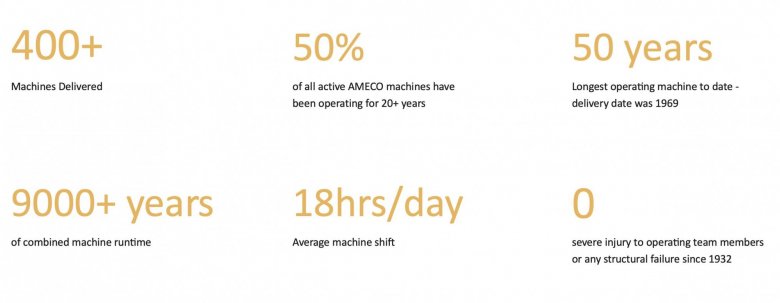

This value proposition is built upon AMECO’s rich set of real-life operational data.

Outcomes

Overall, the new CCR handling system installed by AMECO significantly improved over the previous manual handling process, making CCR management safer, more efficient, and more environmentally friendly.

- Since the machine’s commissioning in 2019, more than 1 million tons of CCR materials have been used to make products like concrete, cement, porcelain tile, wallboard, and roofing shingles. Recycling these materials helped preserve virgin natural resources that would otherwise have been mined to produce cement and wallboard.

- 50,000 tons of gypsum were used to create a sulfur-fertilizer product to meet the increasing demand by the regional farming industry while making the application easier for the farmer thanks to its pelletized form

- $15 million generated from recycling these materials is directly applied as a credit to LGE&KU customers’ utility bills.

Key Metrics

- 26 meters arms

- 112 tons

- 750TPH for reclaiming

- Operating 18 hours a day

- 99.9% uptime outside of planned maintenance

Get in touch with us for your bulk handling equipment needs

Contact usIndustry

- Power Generation

Material

- Gypsum

Capacity (Ton per Hour)

- 350-1000

Solution

- Reclaiming

Storage Configuration

- Longitudinal

- - Indoor

Service

- Supervision & Commissioning

Product

Product type

Dual-Boom Portal Reclaimer (PS2)

Loading rate

750 t/hour

Primary arm length

15 meters

Secondary arm length

7.5 meters

Weight

112 tons